What is a Hydraulic Power Unit (HPU)?

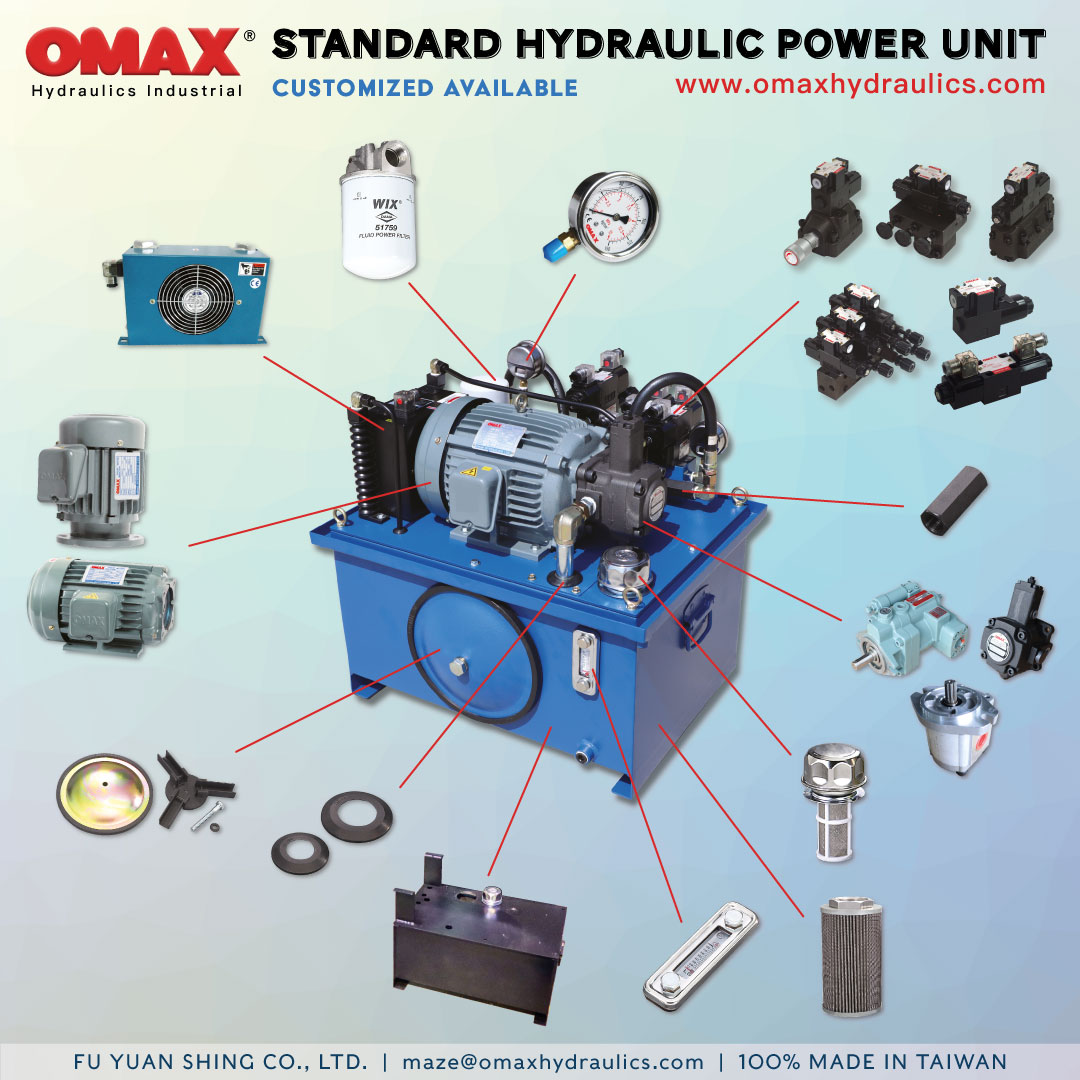

A Hydraulic Power Unit (HPU) is a system that generates and delivers hydraulic power to drive various mechanical operations. It typically consists of a motor, pump, reservoir, and other components that work together to provide the necessary force and flow for hydraulic systems in industrial machinery, construction equipment, and more.

How does the Hydraulic Power Unit (HPU) work?

The Hydraulic Power Unit operates by converting mechanical energy from an electric motor or engine into hydraulic energy using a pump. The pump pressurizes the hydraulic fluid stored in the reservoir, which is then delivered through valves and hoses to actuators or motors. These actuators or motors convert the hydraulic energy into mechanical force, enabling various industrial operations.

OMAX's HPU Available Capacity: 10~3000 Liter

An HPU includes an oil tank, pump, valve, motor, and accessories.

If you need other accessories such as a pressure switch, heat exchanger, accumulator, etc. please contact us.

What is a Hydraulic Power Unit (HPU)?

A Hydraulic Power Unit (HPU) is a system that generates and delivers hydraulic power to drive various mechanical operations. It typically consists of a motor, pump, reservoir, and other components that work together to provide the necessary force and flow for hydraulic systems in industrial machinery, construction equipment, and more.

HPU's Features

- High Efficiency: Delivers consistent power with minimal energy loss.

- Compact Design: Space-saving configurations suitable for various industrial environments.

- Durability: Built with robust materials for long-term, heavy-duty use.

- Customizability: Can be tailored to meet specific operational requirements.

- Advanced Control: Equipped with precision controls for accurate power management.

HPU's Functions

- Power Generation: Converts electrical energy into hydraulic energy.

- Pressure Control: Regulates and maintains the required pressure within the hydraulic system.

- Fluid Management: Circulates hydraulic fluid through the system, ensuring smooth and efficient operation.

- Safety Management: Includes safety features like pressure relief valves to prevent system overloads.

How does the Hydraulic Power Unit work?

The Hydraulic Power Unit operates by converting mechanical energy from an electric motor or engine into hydraulic energy using a pump. The pump pressurizes the hydraulic fluid stored in the reservoir, which is then delivered through valves and hoses to actuators or motors. These actuators or motors convert the hydraulic energy into mechanical force, enabling various industrial operations.

How to make a Hydraulic Power Unit?

1. Design Phase: Define the system requirements, including flow rate, pressure, and application needs.

2. Component Selection: Choose appropriate pumps, motors, reservoirs, valves, and other components based on the design.

3. Assembly: Assemble the components onto a frame or base, ensuring proper alignment and connections.

4. Testing: Test the assembled HPU for performance, leakages, and safety to ensure it meets operational specifications.

5. Fine-Tuning: Adjust controls and settings for optimal performance and efficiency.

Why need a Hydraulic Power Unit?

A Hydraulic Power Unit is essential for any application requiring high force or precise control in moving or lifting heavy loads. It provides the power necessary for hydraulic systems to function, offering reliable performance in demanding environments such as manufacturing, construction, and mining.

What difference between the hydraulic system and the pneumatic/air system?

Hydraulic System:

- Uses liquid (usually oil) as the working medium.

- Capable of generating higher forces due to the incompressibility of the fluid.

- Suitable for heavy-duty applications requiring precise control and constant pressure.

- Generally quieter and more stable but requires more maintenance due to potential leaks and contamination.

Pneumatic/Air System:

- Uses compressed air as the working medium.

- Generates lower forces, making it ideal for lighter applications.

- Faster response times but less precise due to the compressibility of air.

- Easier to maintain with fewer leakage concerns, but can be noisy and less efficient for heavy loads.

How to choose the suitable HPU for my project?

1. Determine Load Requirements: Understand the force and speed requirements of your application.

2. Assess System Pressure and Flow: Select an HPU that provides the necessary pressure and flow rate for your hydraulic system.

3. Consider Environmental Factors: Choose a unit designed for the operating environment (e.g., temperature, humidity, exposure to chemicals).

4. Check for Customization Needs: If your application has specific needs, consider a custom-designed HPU.

5. Evaluate Control and Safety Features: Ensure the HPU has appropriate controls and safety mechanisms to prevent system failure.

Applications for Hydraulic Power Unit

- Manufacturing: Powers hydraulic presses, injection molding machines, and other industrial equipment.

- Construction: Operates cranes, excavators, and other heavy machinery.

- Mining: Drives hydraulic drills, crushers, and other mining equipment.

- Marine: Controls winches, cranes, and steering systems on ships.

- Agriculture: Operates machinery such as tractors, harvesters, and loaders.

Advantages of OMAX Hydraulic Power Units (100% Made in Taiwan)

- High-Quality Manufacturing: Precision-engineered with top-grade materials for reliable performance.

- Customization Expertise: Tailored solutions to meet the unique demands of various industries.

- Technical Proficiency: Backed by over 30 years of experience in hydraulic system design and manufacturing.

- Comprehensive Support: Offers complete hydraulic solutions, from design to after-sales service.

- Competitive Edge: Combining traditional craftsmanship with advanced technology to deliver superior products.

English

English  繁體中文

繁體中文 日本語

日本語